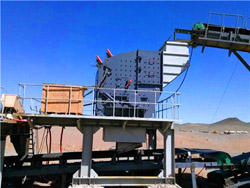

2016-2-26 The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of

احصل على السعر

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below “Dry” crushing

احصل على السعر

2021-9-27 May 15, 2014 Primary crushers Jaw crushers Gyratory crusher PRIMARY CRUSHING Reduction of ore as mined size 1m to 100 mm size. The objects of crushing are

احصل على السعر

Primary Crushing Methods. As part of its investigation into runofmine ore fragmentation Highland Valley Copper discovered the role of primary crushing in the optimisation of mill feed size

احصل على السعر

2020-7-10 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on the variety of

احصل على السعر

2022-4-21 Primary crushing is the first step in crushing the material and can sometimes be sufficient to achieve the desired product size. The primary crusher takes oversized material to

احصل على السعر

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is

احصل على السعر

2015-12-26 Crushers for large giant process plants >2,000 to 200,000 TPD using semi-autogenous mills only require primary crushing and are selected as well as designed based on: Expected Throughput; F80 Top Feed size

احصل على السعر

2017-3-4 There are two kinds of. equipments used for crushing work s. one is by using crushers and other one is by using impacto rs. This diagram illustrates the stages of s ize reduction from 1000mm to 4

احصل على السعر

2020-12-17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along

احصل على السعر

Crushing is typically a dry operation that is performed in two- or three-stages (i.e., primary, secondary, tertiary crushing). Lumps of run-of-mine ore as large as 1.5 m across are reduced in the primary crushing stage to 10–20 cm in heavy-duty machines. In most operations, the primary crushing schedule is the same as the mining schedule.

احصل على السعر

Primary Crushing Methods. As part of its investigation into runofmine ore fragmentation Highland Valley Copper discovered the role of primary crushing in the optimisation of mill feed size Image analysis methods were used to quality the effect of feed size on mill throughput and showed the inpit crushers to be an integral step in the

احصل على السعر

2021-12-13 Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a job. Depending on the setup, primary crushing will take the larger material that has been blasted, excavated, or reclaimed and process it through an impactor, jaw, or gyratory crusher to generate a range of

احصل على السعر

There are four basic mechanical methods to reduce a material by compression, impact, attrition, or shear and most crushers employ a combination of all these crushing methods. Crushers that employ the forces of compression squeeze material between two surfaces, one stationary and the other moving, in order to achieve size reduction.

احصل على السعر

2021-1-12 of mill feed size. Image analysis methods were used to quantify the effect of feed size on mill throughput and showed the in-pit crushers to be an integral step in the preparation of feed to the AG/SAG mills. In the case of Highland Valley, optimal feed size for mill throughput requires a balance between blasting and run-of-mine crushing. While

احصل على السعر

2020-5-6 There are three types of crushers. Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer

احصل على السعر

Crushing The type of crusher required depends on the material being reduced. McLanahan specializes in a variety of crushing solutions for reducing minerals from very friable minerals, such as coal and salt, to hard rock, such as granite, and ore-bearing minerals, such as copper and iron at the primary, secondary and tertiary stages

احصل على السعر

2020-12-17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of

احصل على السعر

2019-6-3 • for primary crushing with a reduction ratio of 6 to 1 • when a relatively coarse product is desired, usually larger than 1-1/2" (38 mm) top size (Mechanical Reduction Methods continued on next page) Mechanical Reduction Methods Impact In crushing terminology, impact refers to the sharp, instantaneous collision of one moving object against

احصل على السعر

2007-2-1 The use of compressive crushing equipment such as gyratory crushers within minerals processing plants can potentially generate large quantities of dust. Remedies to this problem include the retrofitting of shrouds, enclosures, local exhaust ventilation (LEV) systems and water suppression systems. The single or combined application of these

احصل على السعر

Primary Crushing Methods. As part of its investigation into runofmine ore fragmentation Highland Valley Copper discovered the role of primary crushing in the optimisation of mill feed size Image analysis methods were used to quality the effect of feed size on mill throughput and showed the inpit crushers to be an integral step in the

احصل على السعر

2021-9-27 May 15, 2014 Primary crushers Jaw crushers Gyratory crusher PRIMARY CRUSHING Reduction of ore as mined size 1m to 100 mm size. The objects of crushing are 1 size reduction 2 production of a minimum amount of fines. Primary crushing is done on dry material. The basic equipments for primary crushing- 1 Jaw crushers. 2 Gyratory crushers. 3

احصل على السعر

Fused S.A.W. Flux/Slag Crushing Unit. The crushing unit used by Harbert’s Products Inc. was designed and built by A. Beck Enterprises. It was made specifically to crush S.A.W. slag and produces minimal waste that results in less loss of product. The differences in these crushing methods are listed below.

احصل على السعر

There are four basic mechanical methods to reduce a material by compression, impact, attrition, or shear and most crushers employ a combination of all these crushing methods. Crushers that employ the forces of compression squeeze material between two surfaces, one stationary and the other moving, in order to achieve size reduction.

احصل على السعر

2021-1-12 of mill feed size. Image analysis methods were used to quantify the effect of feed size on mill throughput and showed the in-pit crushers to be an integral step in the preparation of feed to the AG/SAG mills. In the case of Highland Valley, optimal feed size for mill throughput requires a balance between blasting and run-of-mine crushing. While

احصل على السعر

大量翻译例句关于"primary crushing" 英中词典以及8百万条中文译文例句搜索。 Translator Translate texts with the world's best machine translation technology, developed by the creators of Linguee.

احصل على السعر

2019-2-15 The primary crushing of Li-ion battery cells of bigger dimensions and of cells with housings made of steel were done in a low speed axial-gap rotary shear (RS). This rotary shear is a twin-shaft machine developed and built by TU Bergakademie Freiberg in 1994 (Woldt, 2005).

احصل على السعر

In general, crushing is carried out in three stages, depending on the desired size of the material. Primary Crushing. This is the first stage of the crushing process. In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm. Secondary Crushing. This is the second stage of crushing.

احصل على السعر

Jaw crushers for primary crushing Voghel. Jaw crushers are primary crushers, rock crushing equipment and other hard and abrasive materials, such as granite, ores or recycled concrete, usually for industrial use. The crushing device consists of a fixed plate and a swivel plate called a jaw. The rock is trapped and crushed between the jaw teeth.

احصل على السعر

2021-10-28 4 Lubricate your machine regularly. Lubricate important parts like mainshaft, bearings, mantle and concave can make the whole production smooth and minimize the downtime. 5 Clean your oil tank if it is contaminated. 6

احصل على السعر