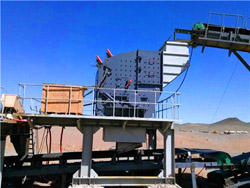

2021-5-12 Ore Crushing Shipping. China small stone ore crushing plant for rock and ores ,stone crushing plant is a stone production line to process rocks and ores into particles. It often consists of primary stone crusher, secondary crusher, and tertiary crusher. stone crushing plant is mainly used in quarry and mine ore rock processing plant.

احصل على السعر

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371-86162511 Email: [email protected]

احصل على السعر

Ore Crushing. Clay is sticky. sizing crusher is best choice for crushing the sticky material. 1. The crushing work conditions: Raw material: clay with 10% of stones The feeding size: 200 The discharged size: less than 100mm Capacity: 300-400t/h Solutions Model: FP 63AS Power: 200KW Weight: 22 ton Dimension: refer to the attached CAD drawing the

احصل على السعر

2019-3-8 1 Ore crushing process and equipment. In the concentrator, the hardness of the ore is 8 ~ 10, the grinding power index is 14 ~ 15 kWh/t, the moisture content is 3%, and the loose density is 1. 69t/m 3, Density 2. 7tm3.

احصل على السعر

The prime ore crushing options take productivity a step higher. The ore crushing choices have innovative designs for sand processing efficacy. MENU Ready to Ship. Paid samples. Min. Order. OK. Price-OK. Supplier Country/Region. Suggestions. India (10) Turkey (1) United States (1) All Countries & Regions. China (32580) Kazakhstan (2)

احصل على السعر

Ore crushing and screening, grinding and classification are essential preparatory work before separation to get proper ore size. There is a balance to keep proper ore size neither too rough (insufficient liberalization) and too fine (over

احصل على السعر

When looking at overall crushing circuit design, having the correct number of crushing stages also helps minimize fines production. A typical crushing circuit will generate a reduction ration between 5:1 and 7:1 for maximum efficiency. For example, to generate a 10mm particle, you’ll want to feed the crusher particles between 50 and 70mm.

احصل على السعر

2017-5-21 Grinding and Flotation. Fine ore at minus 19mm (¾”) sizing is fed at a controlled rate into the open-circuit 2600mm x 3960mm (8’-6 x 13’-0) Hardinge rod mill at an average feed rate of 2,106 STPD or 87.75 STRH. Rod mill

احصل على السعر

2017-2-16 In light of these challenges, in-pit crushing and conveying (IPCC) is a technology that has grown in popularity since it was first implemented in the 1950s. The purpose of an IPCC system is to

احصل على السعر

2015-12-26 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In

احصل على السعر

2021-5-12 Ore Crushing Shipping. China small stone ore crushing plant for rock and ores ,stone crushing plant is a stone production line to process rocks and ores into particles. It often consists of primary stone crusher, secondary crusher, and tertiary crusher. stone crushing plant is mainly used in quarry and mine ore rock processing plant.

احصل على السعر

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371-86162511 Email: [email protected]

احصل على السعر

2019-8-8 The importance of iron ore crushing process; Before dry selection, the lean iron ore requires millimeter-scale fine crushing by the fine crusher. If the particle size of the iron ore is not small enough in the crushing stage, low

احصل على السعر

Hematite and magnetite are the most prominent iron ores. Most of the high-grade hematite iron ores (direct shipping ore (DSO)) are subjected to simple dry processes of beneficiation to meet size requirements. This involves multistage crushing and screening to obtain lump (− 31.5 + 6.3 mm) and fines (approximately − 6.3 mm

احصل على السعر

2012-10-18 Copper Ore Crushing and Grinding Process. First the copper ore is blasted, the copper ore stone will be loaded by way of a durable truck, then be transported to the primary crusher which cuts down on the ores to 8 inches or smaller. Screens size and distribute the classified ore to a number of conveyors, like those above, for transportation for

احصل على السعر

2022-7-1 The Ore Crusher crushes ore blocks, making two dust for each block placed in it. Making an Ore Crusher: To make an Ore Crusher, you will need the following: Nether Brick Fence x1 ** Iron bars x2 Dispenser (facing up)*** x1 Place the Dispenser with the slot facing up at the ceiling. Place Iron Bars on either side of the Dispenser. Place the Nether Brick Fence on top of

احصل على السعر

2015-4-3 In the case of direct shipping ores, it may be as high as 6:1 or 7:1. In the case of low grade ore,a stripping ratio of less than 1.5:1 is often considered as an economic limit. Crushing and screening. Iron ore of merchantable

احصل على السعر

Iron ore is a major raw material required in the manufacturing of steel. Iron-bearing pellets are shipped to Cleveland-Cliffs’ Indiana Harbor facility in East Chicago, Indiana. In 2019, Minorca supplied about 50% of Indiana Harbor’s No. 7 blast furnace’s pelletized iron requirements.

احصل على السعر

2019-8-30 4 Siderite Ore Extraction Method. Siderite is one of the common iron ores. After the accumulation of production practice, there are 4 commonly used beneficiation processes: Gravity separation, Strong magnetic separation, Strong magnetic separation-flotation, Magnetization roasting-weak magnetic separation. 2022-03-31 12:03:04.

احصل على السعر

2015-8-3 Abstract and Figures. The first process that most of the ores or minerals undergo after they leave any mine, is mineral processing or mineral/ ore dressing. It is a process of ore preparation

احصل على السعر

2021-5-12 Ore Crushing Shipping. China small stone ore crushing plant for rock and ores ,stone crushing plant is a stone production line to process rocks and ores into particles. It often consists of primary stone crusher, secondary crusher, and tertiary crusher. stone crushing plant is mainly used in quarry and mine ore rock processing plant.

احصل على السعر

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371-86162511 Email: [email protected]

احصل على السعر

Gold ore crushing. Gold Mineral properties Gold ore is a mineral aggregate with sufficient gold content and can be used industria 1. Hotline +86-21-68101668. Complete set of aggregate equipment solutions Domestic professional production of crushers, screening machines manufacturers Thanks

احصل على السعر

2021-5-18 Jaw crusher is the most common gold ore mining crushing equipment. Jaw crusher crushing ratio can reach 4-6. Therefore, jaw crusher is widely used for crushing all kinds of large size and high hardness materials. Jaw crusher simulates the movement of animals’ two jaws. Movable jaw does periodic reciprocating motion, and sometimes separately

احصل على السعر

2010-3-1 Fortescue is fast-tracking the development of the 'Solomon Stage 1' project, with rail and mine construction commencing during 2011, and

احصل على السعر

2020-8-24 Bayan Obo is rich in iron, rare earth, niobium and other metals. Iron is one of the main minerals here. Iron is harder than most stones. According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces.

احصل على السعر

2022-7-1 The Ore Crusher crushes ore blocks, making two dust for each block placed in it. Making an Ore Crusher: To make an Ore Crusher, you will need the following: Nether Brick Fence x1 ** Iron bars x2 Dispenser (facing up)*** x1 Place the Dispenser with the slot facing up at the ceiling. Place Iron Bars on either side of the Dispenser. Place the Nether Brick Fence on top of

احصل على السعر

2022-7-7 Crushed Ores are obtained from crushing various items. 0.4: Removed Crushed Brass Removed Crushed Ore Milling recipes Changed Crushed Ore returns 0.1: Added Crushed Ores

احصل على السعر

2021-7-12 ABSTRACT Mining consumes approximately 7% of the world’s energy from which almost half goes for comminution. Since the crushers are more energy efficient than mills, it is logic to push down-sizing in crushing stage (s) as far as possible. That has been TON’s strategy in supplying crushers, in 25-Nov-2015.

احصل على السعر

Iron ore is a major raw material required in the manufacturing of steel. Iron-bearing pellets are shipped to Cleveland-Cliffs’ Indiana Harbor facility in East Chicago, Indiana. In 2019, Minorca supplied about 50% of Indiana Harbor’s No. 7 blast furnace’s pelletized iron requirements.

احصل على السعر