2022-5-3 Thus to obtain metallic copper, up to 99 percent of the material mined must be removed as waste. Only the flotation process mentioned above could make this practicable;

احصل على السعر

hammer flotation process rotor manufacturer india. Copper Mobile Flotation Machine Provider In India. A wide variety of flotation machine for ore options are available to you, such as free

احصل على السعر

2022-5-30 The above is the common flotation process of oxide copper ore and mixed copper ore. In the actual beneficiation process, it is recommended to conduct beneficiation

احصل على السعر

2016-5-16 Copper Flotation Process Summary. Flotation of Copper Ores. Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as well as design of the

احصل على السعر

Copper Lead Zinc Ore Flotation Plant Pineer Mining Machinery. The process choice of copper ore flotation is determined by the raw ore properties. Meanwhile, there are many determined

احصل على السعر

2015-4-10 Ore Concentration by Froth Flotation. Remember that only 0.67% of the ore is copper. The copper minerals and waste rock are separated at the mill using froth flotation. The copper ore slurry from the grinding mills is mixed with

احصل على السعر

2016-4-13 Flowsheet for treatment of Copper Sulfide ores rich inminerals such as chalcopyrite with gold and silver as well as arsenopyrite. The above flowsheet is designed for the treatment by flotation of copper as chalcopyrite with gold

احصل على السعر

2017-7-4 economic to acid heap leach the stockpile. The recovery of these copper minerals by flotation or. hydrometallurgy from ores, typically containing 0.5%TCu (open pit mines) and 1-2%TCu (underground

احصل على السعر

2019-2-22 There are several mathematical models that search to optimize resources in different topics and areas. Chile being the largest copper producer in the world, where this natural

احصل على السعر

Xinhai Solutions: Xinhai Mine Research Institute carried on preliminary exploration of its processing conditions and found that the copper recovery rate was the highest in bulk flotation process. Therefore, after discussed with client, Xinhai adopted two stage closed-circuit crushing, one stage closed-circuit grinding, middlings regrinding, copper lead bulk flotation zinc

احصل على السعر

hammer flotation process rotor manufacturer india. Copper Mobile Flotation Machine Provider In India. A wide variety of flotation machine for ore options are available to you, such as free samples.there are 4,186 flotation machine for ore suppliers, mainly lo ed in asia.the top supplying countries are china mainland,algeria, and united states, which supply 99%, 1%, and 1% of

احصل على السعر

2017-4-5 Flotation Plant Copper Ore Ball Mill With Ce Certificate Powder shall be discharged from discharging grating, ending the milling process. Copper Ore Ball mill feature: Ball mill is mainly composed of charging and discharging, cyclone and rotation parts like redactor, minor rotationgear, motor, electric machine, etc. Hollow axis is made of

احصل على السعر

Copper Lead Zinc Ore Flotation Plant Pineer Mining Machinery. The process choice of copper ore flotation is determined by the raw ore properties. Meanwhile, there are many determined factors for copper ore flotation process, like the mineral disseminated particle size, the associated relationship with quartz rock and the gangue mineral types.

احصل على السعر

2018-6-15 A new flotation tailings treatment process was developed for efficient Cu recovery. • An efficient Cu dissolution was achieved in an H 2 O media in presence of pyrite.. The dissolution mechanism of CuFeS 2 has been confirmed to be a multistage reaction.. Fe was always co-dissolved with Cu following a linear relation of C Fe = 38.393 × C Cu.. Over 91% Cu was

احصل على السعر

2017-2-8 Consequently, flotation was attempted to recycle Cu in slag containing copper sulphide components. Three key factors affecting flotation were ascertained, namely, grinding fineness, the collector and the pH value, while the recovery of Cu estimated by ICP and XRF. Copper concentrate grading at 14.47 with 79.66% Cu recovery was obtained, in the

احصل على السعر

2022-7-7 This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) electrolysis. Following mining, transporting, and crushing to a consistent gravel or golf ball-size, the crushed ore is further processed at a mill

احصل على السعر

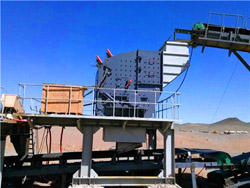

2022-1-25 Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 0.15-0.2mm. Copper ore crushing process. 1.

احصل على السعر

Download scientific diagram results of testing data: (a) Comparison of measured si (Cu-mo) in the flotation concentrate with predicted values, (b) correlation between calculated and observed values.

احصل على السعر

Froth flotation is a relatively expensive process that has been privilege to significant US government funding to define its efficacy to the recycling industry. The process is used to selectively separate hydrophobic from hydrophilic materials [65]. The recycled plastic is ground and treated with a reagent that imparts specific charges to the

احصل على السعر

hammer flotation process rotor manufacturer india. Copper Mobile Flotation Machine Provider In India. A wide variety of flotation machine for ore options are available to you, such as free samples.there are 4,186 flotation machine for ore suppliers, mainly lo ed in asia.the top supplying countries are china mainland,algeria, and united states, which supply 99%, 1%, and 1% of

احصل على السعر

Xinhai Solutions: Xinhai Mine Research Institute carried on preliminary exploration of its processing conditions and found that the copper recovery rate was the highest in bulk flotation process. Therefore, after discussed with client, Xinhai adopted two stage closed-circuit crushing, one stage closed-circuit grinding, middlings regrinding, copper lead bulk flotation zinc

احصل على السعر

stone hammer flotation process Graphite Flotation Process, Ore Beneficiation Equipment 2013-7-30 And flotation machine is the core equipment in graphite flotation process. quartz, pebble, copper ore, iron ore. Application: Jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for

احصل على السعر

Summary Of Fluorite Ore Flotation Process Jxsc Machine. Apr 24, 2019 A great deal of research and production practice shows that flotation is a useful method for recovering fluorite ores, suit for large scale fluorite ore processing, the beneficiation method flotation process and chemical agent varies from the ore characteristics. if you need a

احصل على السعر

2019-7-9 1 Types of copper sulfide ore. (1) Single copper mineral Its ore characteristic is relatively simple, and the only useful component that can be recycled is copper. The gangue minerals are mainly quartz, carbonate and silicate. (2) Copper-sulfur ore Called copper-bearing pyrite. In addition to copper minerals, iron sulfide can be recovered, and

احصل على السعر

2017-2-8 Consequently, flotation was attempted to recycle Cu in slag containing copper sulphide components. Three key factors affecting flotation were ascertained, namely, grinding fineness, the collector and the pH value, while the recovery of Cu estimated by ICP and XRF. Copper concentrate grading at 14.47 with 79.66% Cu recovery was obtained, in the

احصل على السعر

2022-7-7 This process uses a series of physical steps and high temperatures to extract and purify copper from copper sulfide ores, in four basic steps: 1) froth flotation, 2) thickening, 3) smelting, and 4) electrolysis. Following mining, transporting, and crushing to a consistent gravel or golf ball-size, the crushed ore is further processed at a mill

احصل على السعر

2009-8-27 Table 1: Grade/recovery performance of a hypothetical copper ore flotation process. Product % Weight % Cu Assay Feed 100 2.09 Concentrate 10 20.0 Tailings 90 0.1 (a) From Table 1, the Ratio of Concentration can be calculated as F/C = 100/10 = 10. If only assays are available, the ratio of concentration equals (20 0.1)/(2.09 0.1) = 10

احصل على السعر

Download scientific diagram results of testing data: (a) Comparison of measured si (Cu-mo) in the flotation concentrate with predicted values, (b) correlation between calculated and observed values.

احصل على السعر

2022-1-5 Flotation is used in various mining processes, such as gold and coppermining, to recover mineral particles which are finer than 500 micron or 35 mesh. variousparameters influence this process and by that your yield. get price hammer crusher performance analysis binq mining hammer crusher, hammer broken machine, rock crusher, stone crusher.

احصل على السعر